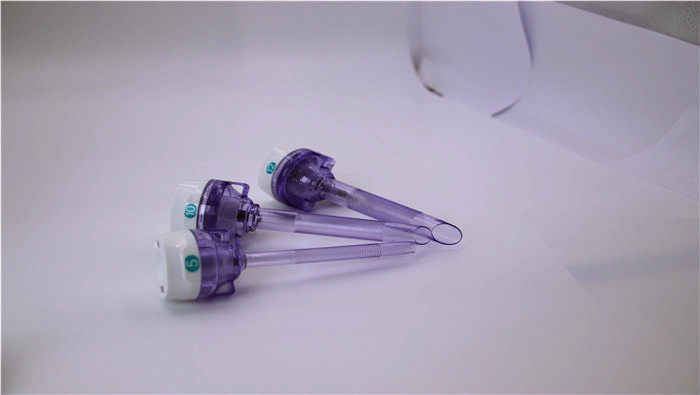

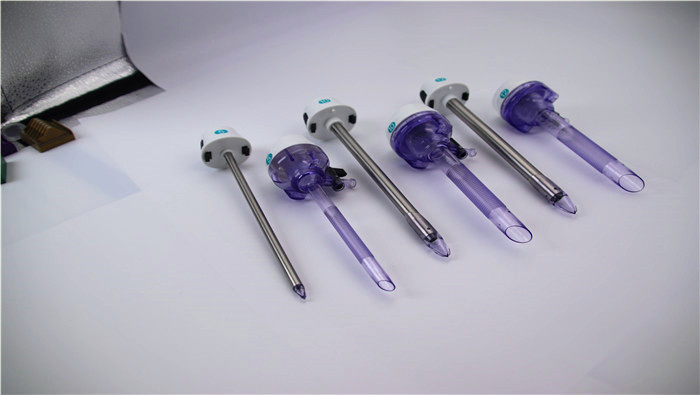

The sealing of a single-use laparoscopic trocar (Trocar) is one of the core functions to guarantee the safety and effectiveness of surgery. Its sealing performance directly affects the maintenance of pneumoperitoneum, the smoothness of instrumentation operation and the control of infection risk. This paper analyzes the importance of sealing function and key influencing factors in the light of clinical needs and engineering principles.

I. Importance of sealing function

Stability of pneumoperitoneum

Maintenance of surgical field: Laparoscopic surgery requires a CO₂ pneumoperitoneum (pressure usually 12-15 mmHg) to provide operating space. Failure of the seal can lead to gas leakage and fluctuations in the pneumoperitoneum pressure, which in turn affects the clarity of the field of view (studies have shown that a drop in pressure of 5 mmHg can reduce the field of view area by more than 30%).

Circulatory safety: persistent gas leaks may force the operator to make up gas repeatedly, increasing the risk of hypercapnia and subcutaneous emphysema.

Infection risk control

Microbial barrier: The sealing structure needs to block the invasion of external microorganisms into the abdominal cavity, as well as prevent intraoperative fluid spillage from contaminating the incision. Clinical data show that a poorly sealed Trocar can increase the incision infection rate by 2-3 times.

Safety of Instrument Handling

Fluid and Gas Leakage Prevention: Seal failure during suction irrigation or electrosurgical use can result in leakage of hot fluids or fumes, which can burn healthcare workers or contaminate the environment.

Energy device compatibility: Fumes generated by ultrasonic scalpel or high-frequency electrosurgical knife may interfere with the operation of the equipment and jeopardize the quality of air in the operating room if they spread through the leakage point.

II. Core Factors Affecting Sealability

1. Seal Material Properties

Resilience: Seals (e.g., silicone gaskets) need to recover their initial shape after repeated insertion/removal of instruments. Silicone (Shore A hardness 40-50) has become the mainstream choice due to its high resilience and fatigue resistance.

Chemical and temperature resistance: need to withstand intraoperative contact with blood, fat and autoclaving (e.g., 121°C/20 minutes), material deterioration can lead to seal failure.

Coefficient of friction control: Low friction surface treatments (e.g. plasma coatings) reduce the resistance to instrument insertion while avoiding seal gaps caused by wear.

2. Seal Structure Design

Multi-stage sealing mechanism:

Primary seal (dynamic seal): Resilient valves (e.g., petal valves, flap valves) for instruments of different diameters, which are required to maintain airtightness in the range of 5-12 mm instruments.

Secondary seal (static seal): Precise fit of the cannula to the puncture core (gap ≤ 0.05 mm) to prevent gas leakage from the instrument channel.

Redundant sealing design: Some high-end Trocars are equipped with secondary sealing caps or removable plugs for maintaining pneumoperitoneum during instrument-free operation.

3. Processing Accuracy

Injection Molding Tolerance: Dimensional deviations of silicone seals (e.g., ±0.1 mm inside diameter) directly affect the fit of the device.

Assembly precision: the coaxiality error between the seal and the casing base should be ≤0.05 mm, and the skewing will lead to localized stress concentration and accelerated wear.

Surface treatment process: sealing surface finish (Ra ≤ 0.4 μm) can reduce the microscopic leakage path.

4. Adaptability to use scenarios

Instrument compatibility: Different brands or models of laparoscopic instruments (diameter, surface texture) may affect the sealing effect. Clinical feedback shows that non-standard instruments can leak up to twice as much as standard instruments.

Frequency of operation: the number of insertions and removals of instruments in a single operation is usually 20-50 times, and seals need to maintain stable performance after cycle testing (≥200 times).

5. Sterilization and storage effects

Sterilization: Ethylene oxide (EtO) sterilization has little effect on the properties of silicone, while gamma radiation may cause a slight hardening of the material (modulus of elasticity increased by 10-15%).

Storage time: Long-term storage (>3 years) may lead to oxidative cracking of the silica gel and a decrease in sealing power.

III. Sealing Test and Verification Methods

Air tightness test

Positive pressure test: Inject 15 mmHg of gas into the Trocar, the leakage rate should be ≤1 mL/min (refer to ISO 15883 standard).

Negative pressure test: simulate intraoperative suction operation and test the seal's ability to resist adsorption and deformation under a negative pressure of 100 mmHg.

Fatigue life verification

After simulating the insertion and removal of instruments for 200 times, the sealing performance should be degraded by ≤10%.

Extreme condition test

Temperature shock: -20 ℃ frozen 2 hours immediately after the airtightness test, to verify the elasticity of the material at low temperatures.

Chemical resistance: immersed in fat emulsion for 24 hours to detect the swelling rate of seals (≤5%).

IV.Direction of Technological Improvement

Material innovation

Enhance chemical resistance and high temperature stability.

Introducing self-repairing coating technology, microscopic scratches can be repaired automatically to prolong sealing life.

Structure optimization

Magnetic Dynamic Seal Valve: Adjust sealing strength through magnetic components, suitable for different diameter instruments.

Multi-layer composite sealing structure: combining the elasticity of silicone with the wear resistance of PTFE to reduce long-term wear.

Intelligent monitoring

Integrated micro-pressure sensor provides real-time feedback on sealing status and warns of leakage risks.

Conclusion

Trocar sealing is the “invisible guardian” of laparoscopic safety, and its performance is affected by material, structure, process and usage scenarios. Future R&D should focus on highly elastic and ageing-resistant materials, adaptive sealing structures and intelligent monitoring technologies to meet the challenges of complex surgical scenarios. Enterprises should establish a full-cycle quality control system from design validation to clinical feedback to ensure the reliability of sealing function under extreme conditions, so as to safeguard the safety of minimally invasive surgery.

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China