DONHO Mold (Suzhou Donghao Precision Manufacturing Co.,ltd)was established in 2008 and is a national high-tech enterprise, specializing in the development of plastic injection molds. Include insert molds, rubber-coated molds, high-temperature molds, precision molds, etc. The market involves industries such as medical devices, automobiles, cleaning appliances, and new energy.

Equipped with MES mold management system. Production planning and process control are fully transparent throughout the entire process. Data visualization and real-time monitoring ensure controllable quality.

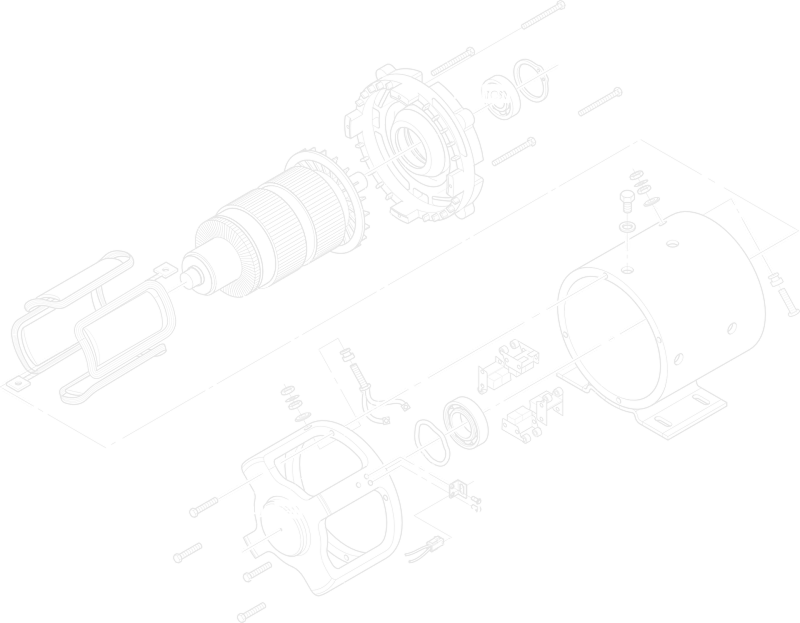

Equipped with advanced processing and testing equipment, we achieve micron-level high-precision processing and control to ensure dimensional accuracy.

The mold processing process realizes EDM/CNC automatic processing and CMM automatic measurement to ensure the efficiency and reliability of the mold processing process

Precision measuring instruments combined with systematic automated management ensure accuracy and efficiency.