I.Physical Damage and Compromised Device Integrity

Vibration, impact, or compression during transportation may cause structural deformation or functional damage to medical devices, directly affecting sterilization efficacy. For example, if vertical steam sterilizers are not properly secured during transit, internal precision components (e.g., pressure sensors, sealing rings) may shift or degrade due to jolts, leading to inaccurate control of sterilization parameters (e.g., temperature, pressure) and reduced reliability. Studies indicate that damage rates for medical devices transported without cushioning measures can reach 5%–8%. Lumened devices (e.g., endoscopes) are particularly vulnerable: micro-cracks in their channels from collisions may harbor residual microorganisms or organic matter, resulting in sterilization failure.

II.Environmental Temperature and Humidity Effects on Sterilant Residues

Fluctuations in temperature and humidity during transportation may accelerate the release or degradation of sterilant residues. For ethylene oxide (EO)-sterilized devices, temperatures exceeding 40°C during transit can trigger accelerated EO off-gassing, increasing toxicity risks on device surfaces. Conversely, high humidity may cause chemical sterilants (e.g., hydrogen peroxide) to degrade prematurely, reducing sterilization effectiveness. Data show that EO-sterilized devices transported in high-temperature, high-humidity environments require extending the aeration time by 30%–50% to avoid allergic reactions in patients.

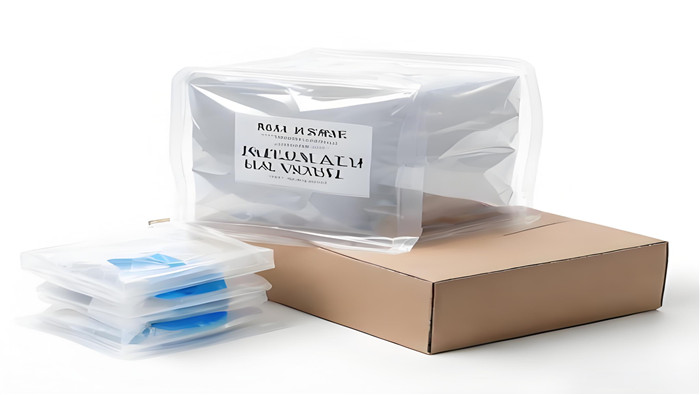

III.Packaging Breaches and Microbial Recontamination

Packaging integrity is a critical barrier to maintaining sterility. Friction, punctures, or stacking pressure during transit can compromise packaging (e.g., tears, seal failures), allowing airborne microbes to infiltrate and contaminate sterilized devices. Per ISO 11138 standards, loss of packaging seal integrity increases microbial contamination risk by over 70%. Long-distance transportation exacerbates material fatigue due to vibration and temperature shifts, leading to sealant detachment or shrinkage. For instance, paper-based packaging softens in humid conditions, reducing compressive strength by 50% and raising breach risks.

IV.Transportation Duration vs. Sterilization Expiry Limits

The shelf life of sterilized devices may conflict with transit time. For example, polyethylene-packaged devices sterilized by gamma irradiation may experience accelerated material degradation if exposed to ultraviolet light (e.g., sunlight) during transit, shortening their effective period. Research reveals that non-light-protected irradiated devices lose 20%–30% of their shelf life on average, with increased brittleness risks. Similarly, low-temperature plasma-sterilized devices may lose sterilant efficacy due to temperature fluctuations during prolonged transit, necessitating re-sterilization.

V. Operational Compliance and Indirect Impacts of Staff Training

Transport personnel practices indirectly impact sterility maintenance. Non-compliant loading (e.g., overstacking) may obstruct airflow within sterilization pouches, causing condensate buildup and biofilm formation. Rough handling may scratch optical components (e.g., laparoscopic lenses), impairing post-operative functionality. Statistics indicate that improper transportation practices contribute to a 12% resterilization rate, significantly increasing hospital operational costs.

VI. Risk Amplification Under Special Transport Conditions

For sterilized devices requiring cold-chain logistics (e.g., implants with bioactive coatings), temperature deviations may denature or detach coatings, compromising sterilization efficacy and triggering immune rejection. For example, temperature-sensitive devices transported outside 2–8°C for over 4 hours exhibit a 40% drop in biocompatibility compliance. Cross-border transportation also risks packaging rupture from atmospheric pressure changes, necessitating nitrogen-filled packaging for protection.

Conclusion:

Systemic Optimization of Transportation Chains to Safeguard Sterilization

Transportation methods impact sterilization efficacy across physical, chemical, and biological dimensions. Mitigation strategies include:

Enhanced packaging durability (e.g., multilayer composite films);

Strict environmental monitoring (e.g., IoT-enabled sensors);

Improved staff training (e.g., simulated handling scenarios).

By 2030, smart transportation systems are projected to reduce sterilization-related transit losses to below 2%, ensuring robust global healthcare safety.

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China