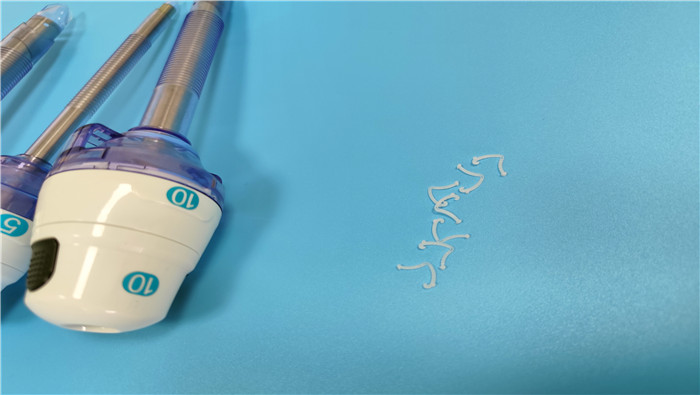

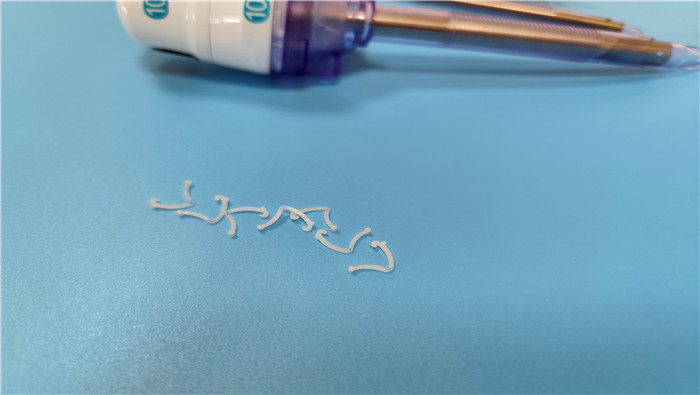

POM (polyoxymethylene) is widely used in disposable tissue closure clips (e.g., Hem-o-lock clips) because of its high rigidity, abrasion resistance, and dimensional stability. Different sterilization methods may significantly affect the performance, safety and clinical outcomes of POM materials, including material degradation, mechanical property changes, biocompatibility and dimensional stability. The effects and potential risks of sterilization methods are systematically analyzed below in conjunction with the effects of pH.

I. Ethylene Oxide (EtO) Sterilization

Material Chemical Stability Impacts

Gas Penetration and Residual: EtO molecules may penetrate into the interior of the POM material, and if not adequately resolved (e.g., insufficient aeration time), residual EtO and its by-products (e.g., epichlorohydrin and ethylene glycol) may form a weakly acidic environment. Glycol may be slightly acidified in water (pH ≈ 5-6), and prolonged exposure may accelerate the hydrolysis of POM, leading to molecular chain breakage.

Hydrolysis risk: High temperature and high humidity environment (EtO sterilization humidity 40-80%) may accelerate the hydrolysis of POM, generating traces of formaldehyde and formic acid, which further reduces the local pH (pH≈3-4) and triggers surface embrittlement of the material.

Changes in mechanical properties

Decrease in clamping force: Acidic environment accelerates the degradation of molecular chains. After multiple EtO sterilizations (>20), the modulus of elasticity of POM may decrease by 5%-10%, resulting in insufficient clamping force.

Failure of locking mechanism: Residual acid may corrode the locking engagement surface, increasing the risk of accidental unlocking.

Countermeasures

Forced resolution process (50°C/48h ventilation) to ensure residue ≤ 4μg/cm² (ISO 10993-7 standard);

Adding alkaline neutralizer (e.g. Calcium Carbonate) to the material formulation to buffer the effect of acidic by-products.

II.Gamma Sterilization

Radiation Degradation Effects

Molecular Chain Breakage and Oxidation: High-energy rays (25-50kGy) cause breakage of the main chain of POM, and at the same time trigger a free radical oxidation reaction to produce carboxylic acids (e.g. formic acid), which lowers the pH value of the surface of the material (pH ≈ 4-5). Acidic environment may accelerate the expansion of cracks within the material.

Developer Failure: For inclusions containing barium sulfate, acidic environments may cause developer particles to fall out and developer clarity to decrease.

Functional risks

Increased brittleness: acidic degradation products weaken the toughness of the material, impact strength decreases by 20%-30%, and microcracks are likely to occur intraoperatively.

Biocompatibility risk: Localized pH reduction may irritate surrounding tissues and trigger inflammatory reactions.

Improvement direction

Add anti-radiation stabilizers (e.g., hindered amines) and pH buffers (e.g., magnesium oxide) to reduce the generation of oxidation and acidic by-products;

Adopt low-dose radiation (≤25kGy) and optimize the uniformity of dose distribution.

III. E-beam Sterilization

Local Thermal Effects and Chemical Changes

Surface Overheating and Oxidation: E-beam energy concentration may lead to the local temperature of the clamp body >100℃, triggering the oxidation of the POM surface to generate acidic substances (e.g., formic acid), and the local pH value is lowered (pH ≈ 4-6).

Dose control: High dose rates (>10kGy/min) aggravate material degradation, and beam parameters need to be strictly controlled to minimize heat accumulation.

Limitation of penetration

The limited penetration depth of the electron beam (about 1-3cm) may lead to incomplete sterilization inside the thick-walled body, and residual microorganisms are more likely to multiply in an acidic environment.

IV. Autoclave Sterilization

Humid Heat Environment and Hydrolysis Reaction

Accelerated Hydrolysis: High temperature (121°C) and high humidity environment, POM water absorption increases (>0.5%), hydrolysis generates formaldehyde and formic acid, which reduces the overall pH value of the material to 3-4. Acidic environments significantly reduce the creep resistance of the material (down 30%-50%).

Dimensional deformation: The synergistic effect of moisture and heat expansion and acidic corrosion results in a latch gap deviation of >0.1mm and an elevated risk of closure failure.

Clinical applicability

Autoclaving is not usually applicable to POM due to its poor resistance to moisture and heat and severe acidic degradation.

V. Comprehensive analysis and response strategy of the influence of acidity and alkalinity

Sterilization method preference

EtO sterilization: need to reduce the erosion of acidic residues on the material by sufficiently resolving and adding buffer;

Low-dose gamma radiation: combined with stabilizers and pH adjusting agents to inhibit oxidation and the generation of acidic by-products;

E-beam sterilization: optimize the beam current parameters to avoid localized overheating and to reduce the formation of acidic substances.

Direction of material modification

Copolymer POM: Compared with homopolymer POM, the hydrolysis resistance of copolymer is improved by 20%-30%, which is more tolerant to acidic environment;

Acid and alkali buffer additives: Add inorganic alkali (e.g., magnesium hydroxide) or organic buffer to neutralize the acid generated by degradation, and maintain the material pH-neutral (6-8).

Process Control Points

Perform material pH stability test (e.g., immersion test) before sterilization to evaluate the effect of different sterilization methods on acidity and alkalinity;

Test the pH of the surface of the fixture after sterilization (contact method or extract test) to ensure that it meets the biocompatibility requirements (pH 5-8).

Conclusion

The effect of sterilization methods on POM closure clips is not limited to mechanical properties and biocompatibility; changes in pH may further threaten product safety by accelerating material degradation and triggering inflammatory reactions. The negative impacts of acidic and alkaline environments on products can be significantly reduced through preferred sterilization methods (e.g., EtO combined with full resolution), material modification (copolymerized POM with buffers), and process optimization (pH monitoring and neutralization). In the future, real-time pH monitoring technology needs to be developed and combined with new sterilization processes (e.g., low-temperature plasma) to achieve full life-cycle stability control of POM closure clips.

Preferred Sterilization Methods

EtO Sterilization: need to reduce the erosion of acidic residues on the material by fully resolving and adding buffer;

Low Dose Gamma Ray: combining stabilizers and pH adjusting agents to inhibit oxidation and the generation of acidic by-products;

E-beam Sterilization: optimizing the beam current parameter in order to avoid localized overheating and to reduce the formation of acidic substances.

Direction of material modification

Copolymer POM: Compared with homopolymer POM, the hydrolysis resistance of copolymer is improved by 20%-30%, which is more tolerant to acidic environment;

Acid and alkali buffer additives: Add inorganic alkali (e.g., magnesium hydroxide) or organic buffer to neutralize the acid generated by degradation, and maintain the material pH-neutral (6-8).

Process Control Points

Perform material pH stability test (e.g., immersion test) before sterilization to evaluate the effect of different sterilization methods on acidity and alkalinity;

Test the pH of the surface of the fixture after sterilization (contact method or extract test) to ensure that it meets the biocompatibility requirements (pH 5-8).

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China