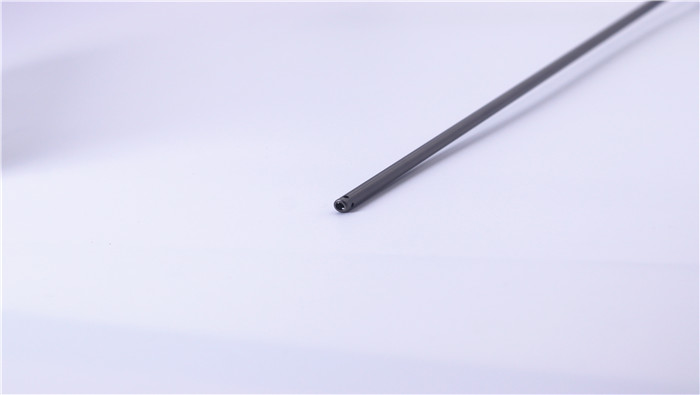

The flushing tube and suction tube in disposable flushing and suction device are the core components, and their manufacturing process is crucial to the performance and quality of the product. The following will be from the material, design, technology, processing, assembly and other perspectives, a detailed analysis of the key points that need attention in the manufacturing process.

I. Material selection

1. Material performance: flushing tube and suction tube need to withstand a certain pressure and liquid flow, so it should be selected with good pressure resistance, corrosion resistance and biocompatibility of the material. Commonly used materials include medical grade PVC, polyurethane (PU) or silicone rubber. These materials not only have excellent physical properties, but also ensure compatibility with human tissue.

2. Material purity: In order to ensure the sterility and safety of the product, the selected material should be of high purity and avoid containing harmful impurities or additives. At the same time, the material should be easy to clean and sterilise to meet the requirements of medical use.

Ⅱ, The main points of design

1. Size and shape: The size and shape of the flushing tube and suction tube should be designed according to the surgical needs. For example, the tube diameter should be sized to ensure sufficient flow and pressure while avoiding excessive damage to the patient's tissues. The shape can be flexible to better fit the contours of the surgical site.

2. Connection structure: The connection structure of the flushing tube and suction tube with other components should be designed to be firm and reliable to avoid loosening or leakage during use. Threaded connection, snap connection or welding can be used to ensure the stability and sealing of the connection.

Ⅲ, The manufacturing process

1. Extrusion moulding: For materials such as PVC or PU, extrusion moulding process can be adopted. Through precise mould design and temperature control, pipes with uniform wall thickness and smooth surface can be produced. During the extrusion process, attention needs to be paid to the melting of the material and the extrusion speed to ensure the quality and dimensional accuracy of the pipe.

2. Injection moulding: For components that require complex shapes or structures, such as connectors or valves, the injection moulding process can be used. Injection moulding has the advantages of high efficiency, precision and easy automation, and can produce parts with complex shapes and high precision.

Ⅳ, Processing treatment

1. Surface treatment: In order to improve the abrasion resistance and biocompatibility of the flushing tube and suction tube, the surface of the tube can be treated, such as spraying or coating. These treatments can not only improve the service life of the tubes, but also reduce the irritation and damage to the patient's tissue.

2. Cutting and assembling: After the tube is processed, it needs to be cut and assembled precisely. When cutting, the length and end surface of the tube should be ensured to be flat; when assembling, the matching precision and sealing between the components should be ensured.

V. Assembly and Test

1. Assembly process: The assembly of the flushing tube and suction tube with other parts should be carried out with precise process and equipment to ensure the quality and efficiency of the assembly. In the assembly process, attention needs to be paid to the co-ordination and positioning between the components to avoid over-tightening or over-loosening.

2. Performance test: After the assembly is completed, it is necessary to carry out performance tests on the flushing attractor, including flow test, pressure test and sealing test. These tests can ensure that the product has stable performance and reliable quality in the process of use.

In summary, the flushing tube and suction tube of disposable flushing suction device need to pay attention to many points in the Donho company manufacturing process, from material selection to design, process, processing, assembly and testing and other aspects need to be strictly controlled. Only by ensuring the quality and precision of each link can we produce disposable flush suction devices with excellent performance and reliable quality.

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China