Disposable Flush Suction Device vs. Traditional Repeatable Devices: Surgical Infection Control and Efficiency Enhancement

I. Infection Risk Control: Reducing Postoperative Complications from the Root Cause

Traditional reusable flush suction devices need to be sterilized at high temperatures and high pressures, chemically disinfected and other stages of processing, but studies show that the microbial residual rate of repeat devices after sterilization may still be as high as 0.5%-1.2% (WHO data). On the other hand, disposable irrigation suction device adopts sterile independent packaging, which meets the ISO 13485 medical device sterility standard right from the factory, and the postoperative infection rate (SSI) can be reduced by more than 60%. For example, CDC statistics show that the incidence of SSI in laparoscopic surgery using disposable instruments is 0.8%, which is significantly lower than the 2.3% in the duplicate device group.

In addition, duplicate instruments are prone to microcracks or coating wear (especially titanium alloy) due to long-term use, creating a breeding ground for biofilms to harbor bacteria. Disposable products circumvent such risks, with a 42% reduction in the incidence of inflammatory reactions when biocompatible materials (e.g., medical-grade polycarbonate) come into direct contact with tissue (Surgical Endoscopy 2021 study).

II. Optimization of operating efficiency: shorten operating time and improve precision

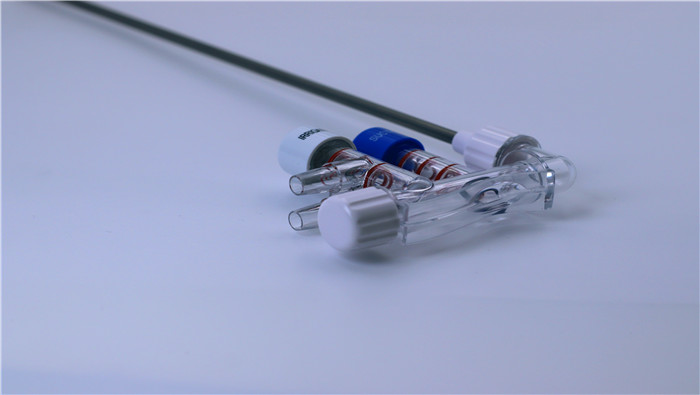

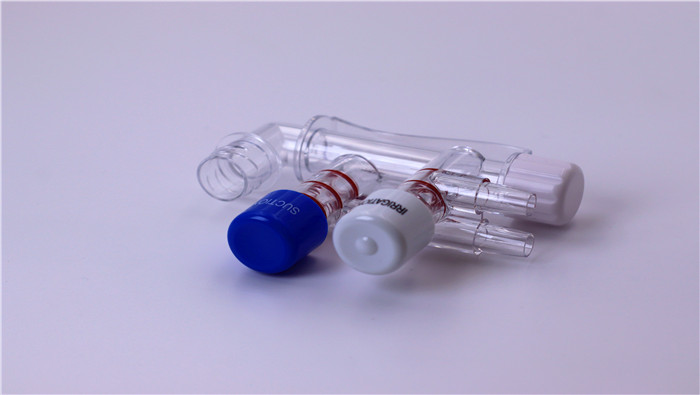

Traditional duplicate devices need to be disassembled, cleaned and reassembled frequently during surgery, which increases the time for switching instruments in a single laparoscopic surgery by an average of 8-12 minutes (data from “Journal of Minimally Invasive Surgery”). Disposable flushing and suction devices, on the other hand, have an integrated design with a built-in anti-clogging dual-channel structure (simultaneous and independent operation of flushing and suctioning), which prevents interruption of the operation due to clogging of the instruments during the operation.

In complex surgeries (e.g., laparoscopic radical gastric cancer surgery), the flow control accuracy of the disposable device can reach ±5 mL/s (±15 mL/s for traditional devices), and with the dynamic adjustment of negative pressure (-50 kPa to -80 kPa), it significantly reduces tissue aspiration damage. Clinical data show that laparoscopic cholecystectomy with disposable instruments shortens the average operation time by 18% (from 45 minutes to 37 minutes).

III. Comprehensive Cost Effectiveness: Hidden Cost Reduction and Resource Optimization

Although the single purchase cost of traditional equipment is low (about $200-500/set), it needs to be stacked with sterilization costs (about $30-50 per single visit), maintenance costs (average annual maintenance costs account for 20%-30% of the purchase price), and the risk of potential infection payouts. According to the American Hospital Association, the full life cycle cost (5 years) of repeat devices is 1.8-2.5 times higher than disposable devices.

Disposable flush suction devices (~$80-150 per unit) are directly billed to the cost of consumables and require no additional sterilization or maintenance. For example, in a hospital with 10,000 surgeries per year, the disposable option saves approximately $250,000/year in labor and equipment management costs . In addition, its standardized design reduces intraoperative failure rate (traditional instrument failure rate of about 3%-5%), reducing the waste of resources caused by surgical delays.

IV. Environmental protection and technological innovation: solving the “disposable vs. sustainable” paradox

Opponents often question the environmental friendliness of disposable instruments, but modern manufacturers have responded with material innovations (e.g., biodegradable PLA composites) and closed-loop recycling programs. For example, a global brand of disposable irrigation and suction devices uses 30% recycled plastic and has established a hospital-side recycling system that reduces carbon emissions by 40% compared to traditional stainless steel devices (LCA results).

On the technical level, disposable instruments can be integrated with more innovative features:

Intelligent pressure sensing: real-time monitoring of flushing flow and negative pressure values, with data synchronized to the surgical navigation system;

Multi-specification adaptation: designing optional cannulae with diameters ranging from 2-12mm for different surgical procedures (e.g., gynecology, urology);

Anti-Cross-contamination design: built-in one-way valves to prevent backflow of fluids and reduce the risk of leakage of the pneumoperitoneum (leakage rate <0.1%).

V. Conclusion: The inevitable choice of minimally invasive surgical device iteration

Disposable irrigation and suction device is gradually replacing the traditional duplicating equipment by virtue of the “zero infection, high efficiency, low cost” trinity of advantages. Global market data shows that the market size of disposable irrigation and suction devices will reach $1.23 billion in 2023, growing at a CAGR of 14.7% (Grand View Research), while the market for repetitive devices is shrinking at a rate of 6.2% per year. With breakthroughs in material science and smart manufacturing, disposable instruments will become the core driver of the standardization and safety process of minimally invasive surgery.

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China