I. Raw material validation

Biocompatibility

According to ISO 10993 series of standards to complete the evaluation of cytotoxicity, sensitization and acute systemic toxicity. If it contains contrast agents (e.g. barium sulfate), the risk of migration of the ingredients needs to be additionally evaluated.

The material should pass the performance stability test after several sterilization cycles (e.g., ethylene oxide, gamma radiation) to ensure that there is no deterioration phenomenon such as yellowing and embrittlement.

Mechanical Properties

Verify the tensile strength and elongation at break of POM to comply with the industry standard for medical device materials.

Establish a batch consistency management system for raw materials, and ensure supply chain stability through spectral analysis (e.g. DSC, FTIR).

II. Production process validation

Injection molding control

Determine the mold temperature, injection pressure, holding time and other parameter windows through experiments to ensure that the dimensional tolerance of the clamp body meets the design requirements (e.g., micron-level precision).

Monitor material crystallinity (e.g. β crystal type percentage) to optimize creep resistance.

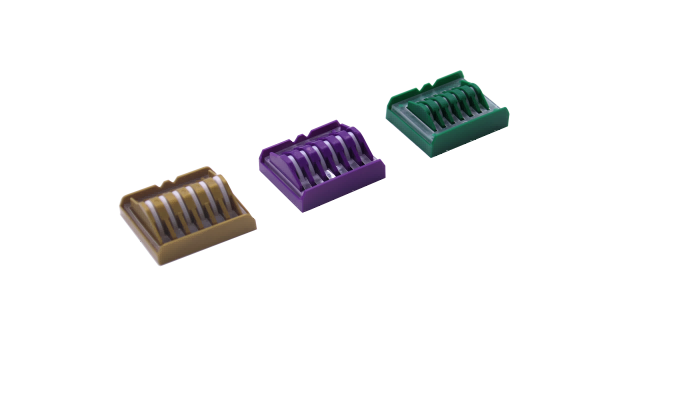

Validation of the latch mechanism

Verify the fit precision of the latch and clamp arm (e.g. strict tolerance control) and ensure structural reliability through fatigue testing (simulating multiple opening and closing cycles).

The clean room needs to comply with ISO 14644 standards to control particulate contamination in the production environment.

III. Sterilization and Packaging Validation

Sterilization validity

Verify the sterilization process according to international standards (e.g. GB 18279, ISO 11137) to ensure that the sterility assurance level is up to standard.

Control sterilization residues (e.g. ethylene oxide, ECH) to meet the biosafety threshold.

Packaging Reliability

Test the heat seal strength and accelerated aging performance to ensure the seal integrity during transportation and storage.

IV. Functional Verification

Clamping performance test

Verify the initial clamping force and long-term retention force of isolated tissue models (e.g. porcine mesenteric blood vessels) to ensure that they meet clinical requirements.

Dynamic anti-slip test verifies the stability of the clamp and simulates complex intraoperative stress scenarios.

Visualization and Compatibility

Evaluate the imaging clarity of developing points (e.g., DSA, CT) to ensure intraoperative positioning accuracy.

Verify the compatibility of the device with imaging equipment (e.g., MRI without artifacts).

V. Risk Management and Compliance

Risk Control

Identify potential failure modes (e.g. latch breakage, insufficient clamping force) through FMEA analysis and develop control measures (e.g. online inspection process).

Regulatory Compliance

Satisfy the requirements of the domestic “Good Manufacturing Practice for Medical Devices” and international regulations (e.g. FDA 21 CFR, EU MDR), and complete the documentation of the whole process.

VI. Production Conformance Verification

Process Capability

Key dimensions through the statistical process control (SPC) to ensure the stability of mass production (such as CPK ≥ 1.67).

Continuous production batches verify performance consistency and meet industry acceptance standards (e.g., bioburden control).

Conclusion

Design validation needs to build a full-dimensional system covering “material-process-function-compliance”, focusing on raw material stability, process robustness and sterilization residue control, while ensuring reliable function through clinical simulation testing. Companies should establish traceable validation documents (DQ/IQ/OQ/PQ) to provide scientific basis for product registration and mass production.

+86 18361958211

marketing@cndonho.com

+86 18361958211

No.2 Zhiwei Road, Qiandeng Town, Kunshan City, Jiangsu Province, China